At PCB Advance, we understand that PCB layout is the foundation of every successful electronics project. It’s the intricate dance of components, traces, and connections that bring your design to life. With our advanced PCB layout services, we meticulously transform your schematic into a functional and efficient circuit board, ensuring optimal performance and manufacturability.

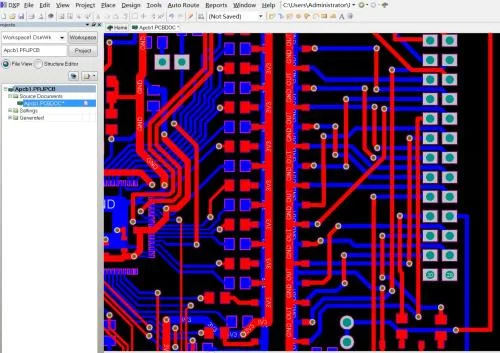

In the past, schematic drawings and PCB layouts were meticulously hand-crafted, and those skilled in these arts were highly sought after. However, in today’s age, ECAD tools have revolutionized the creation of these PCB diagrams. Transitioning from a schematic to a PCB layout has become an automated process facilitated by computer software.

Choose the Circuit Board Dimensions

Commence the process by selecting the appropriate dimensions for the circuit board. While most ECAD tools offer preset board sizes and customizable options for area and thickness

Formulate the Stack Configuration

After defining the board size, materials, layer count, and type, proceed to establish the stack configuration. This foundational step lays the groundwork for the subsequent design process.

Arrange Component Placement

Efficiently organizing components is the next pivotal step. Post partitioning and adhering to licensing rules, position the components on the board. This meticulous arrangement is fundamental to the successful construction of the board.

Navigate Routing and Tracing

Routing and tracing entail wiring, a task often considered the most intricate in PCB layout. This complexity intensifies in the case of multi-layer boards with a significant number of vertical through-holes (PTH) that transmit signals internally and to the ground plane. Adhering to proper spacing and gap regulations during track routing is crucial.

Conduct Thorough Checks

Before finalizing the PCB design, it’s essential to perform meticulous checks for any errors. Integrate a Design Rule Check (DRC) assessment to verify if your design aligns with the prescribed layout guidelines and restrictions. These regulations should align with the CM’s Design for Manufacturability (DFM) guidelines to ensure manufacturability.